Clear Poly Tabs are available in quantity cases and individual rolls.

Clear Wafer Seals are ideal for mailing projects that are multicolor.

About Clear Poly Tabs

There are many different manufacturers of Clear Tabs but, all clear tabs are not the same. WaferSeals.com has developed a Trouble Free Clear Tab that eliminates the most common problems associated with clear tab application. We use a 2.5mil clear polystyrene (not 2.0 mils). 2.5 is the correct rigidity for fast tab application. We also avoid fracturing the liner when die cutting to eliminate web breaks when tabbing. For more information about the quality of WaferSeals.com tabs see our quality assurance page and warranty.

Clear Wafer Seals are ideal for mailing projects that are multicolor. Clear Tabs will not be as noticeable as white tabs, therefore, they will not distract the recipient away from the mailed message.

Satisfaction Guaranteed!

If you're not completely satisfied with our product, price or service, we'll make it right fast!

- Better Quality

- Fewer Splices

- Compatibility with most tabbers

- Faster Run Speeds

WaferSeals.com is all about Quality, Reliability and Price. You can't buy a better wafer seal. We guarantee it!!!

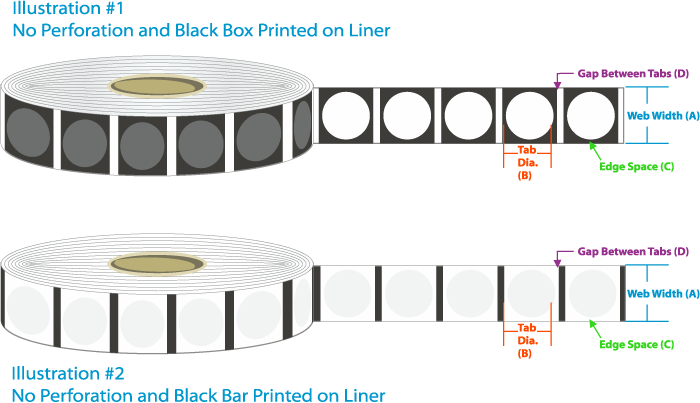

Below are the specifications and illustrations which will help you select the correct Clear Poly Tab for your application.

If you have special requirements please call 855-444-9479.

2.5 Mil Clear Poly Tabs

(supplied on 3" cores)

| Tab Size | Roll Count | Perf | Liner Print | Web Width A |

Tab Dia. B |

Edge Space C |

GAP Between Tabs D |

Perfs per Tab E |

Roll Dia. F |

Wt. per Case | Illust. |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 2" | 7,500 | None | Bar | 2-1/8" | 2" | 1/16" | 1/8" | N/A | 11.5" | 23# | 2 |

| 1-1/2" | 4,000 | None | Bar | 1-5/8" | 1-1/2" | 1/16" | 1/8" | N/A | 7.63'' | 38# | 2 |

| 1-1/2" | 10,000 | None | Bar | 1-5/8" | 1-1/2" | 1/16" | 1/8" | N/A | 11.87'' | 26# | 2 |

| 1-1/2" | 20,000 | None | Bar | 1-5/8" | 1-1/2" | 1/16" | 1/8" | N/A | 16.50" | 47# | 2 |

| 1" | 5,000 | None | Box | 1-1/8" | 1" | 1/16" | 1/8" | N/A | 7.5" | 29# | 1 |

| 1" | 10,000 | None | Box | 1-1/8" | 1" | 1/16" | 1/8" | N/A | 10" | 15# | 1 |

| 1" | 20,000 | None | Bar | 1-1/8" | 1" | 1/16" | 1/8" | N/A | 13.75" | 28# | 2 |

Material Tolerances and Product Specifications

CLEAR POLYSTYRENE TABS

| Material |

|

| Adhesive |

|

| Liner |

|